LABTECH sales representation

The Labtech Engineering is one of the biggest producers in the world of laboratory polymer processing machines. The products of Labtech Engineering are suitable for laboratory uses of universities and high schools, laboratory and research as well as producing uses of manufacturing companies. All products are made according to CE norms and they come with 2-year warranty.

Labtech Engineering products can be divided into following cathegories:

Extruders

Single Screw:

Ø 12.5, 20, 25, 30, 40 a 45 mm, 30 L/D available as vented and as nonvented or PC control

Twin Screws:

Ø26 mm, 32-60 L/D

Ø20 mm, 32-60 L/D

Ø16 mm, 32-48 L/D Table Top design

Ø12 mm, new MicroCompounder

Flat Film and Sheets Extrusion

It is a compact unit on rails. The unit is equipped with three rolls with the possibility to adjust it as well in vertical and horizontal position as in arbitrary angle. Parts of this device include a cooling roller conveyor, haul off, wind up station and water/oil temperature units. Maximal roller width is 500 mm. It is possible to use the unit for both the Chill Roll system with using air knife and for calendering line. Roll revolutions are reversible.

Film Blowing Extrusion

It is possible to choose Single layer film blowing line (with one extruder) and Co-Ex film blowing line (with possibility up to 11 extruders). Available versions are:

The LF-250 type comes with rollers that are 250 mm in width, a motorized height adjustable tower with adjustments from 1 - 2 m and lay flat foil with a width of up to 200 mm

The LF-400 type comes with rollers that are 400 mm in width, a motorized height adjustable tower with adjustments from 2,5 - 3,5 m and lay flat foil with a width of up to 350 mm

The LF-600 type comes with rollers that are 600 mm in width, a motorized height adjustable tower with adjustments from 3,2 - 4,2 m and lay flat foil with a width of up to 550 mm

The LF-800 type comes with rollers that are 800 mm in width, a motorized height adjustable tower with adjustments from 4,2 - 5,2 m and lay flat foil with a width of up to 750 mm

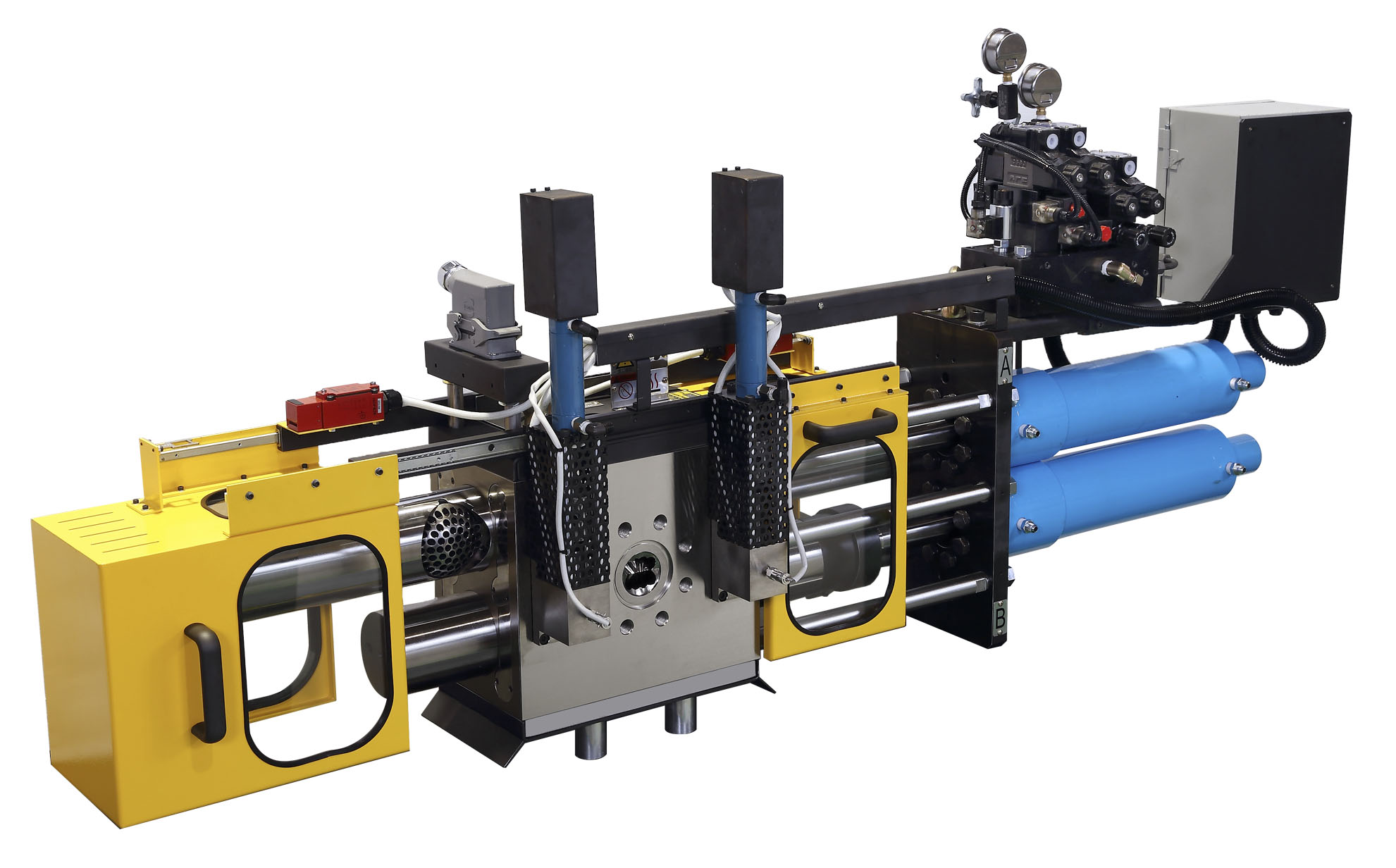

Extrusion blow molding

Fully automatic, hydraulic control (50 bar) device for blow molding of parisons to 125 ml capacity is equipped with colored LCD touch screen. It is possible to connect it easily to single screw from ø 20-30 mm and even to double screw extruders. You can connect co-ex option as well.

Pipe, Tube, Hose, Small profiles extrusion

The machine is designed for tubes and hoses extrusion to ø 25 mm. The die is designed in a way that ensures easy change of dimensions of the hose, just replace the die (outer ring) and mandrel. A stainless steel cooling bath with vacuum calibration and spray nozzles and a haul off unit are included with the line. A wind up single/double station with traverse mechanism or with cutting unit is an optional addition.

After modifications it is possible to deliver this type of line even for production of 3D printer strands with extrusion speed up to 40 m/min.

Two-Roll mills

Hydraulic Presses

Mixers

Pelletizers

For more information do not hesitate to contact us.

SCHWING sales representation

Working from their manufacturing headquarters in Germany, SCHWING designs, engineers manufactures and markets the most advanced Thermal Cleaning Systems since 1969. Valuable experience resulting in industrial leadership and excellent processes with perfect results for the plastics and fiber industry.

Thermal ovens are possible to use for all types of polymers.

SCHWING THERMAL OVENS TYPES:

VacuClean

VACUCLEAN gently removes organic contamination from heat resistant metal parts by melting it off and thermal decomposition under vacuum.

ADVANTAGES:

Especially gentle cleaning of temperature sensitive parts and tools

Only electricity and water required

Catalytic converter for off-gas cleaning

Especially recommended for:

Spinnerets, melt-blown and spunbond dies

Filter bundles, leaf disks

Blown film die heads

Extruder screws

InnovaClean

INNOVACLEAN removes all organic contamination (including halogenated polymers) from heat resistant metal parts by thermal decomposition in a fluidized bed.

ADVANTAGES:

Very short cleaning times

Suitable for all polymers (inl. PVC, PTFE, PEEK)

Highest flexibility

Especially recommended for:

Spinnerets, assembled spin packs

Breaker plates

Special profile dies

Hot runners

MaxiClean

MAXICLEAN is a gas-heated thermal cleaning system. It removes all organic contamination from large metal parts and tools by thermal oxidation.

ADVANTAGES:

For large parts and machine tools

Applicable for large amount of polymers

Suitable for most polymers

Especially recommended for:

Filter bundles

Extruder screws

Large extrusion and pelletizing dies

Large hot runners

CompactClean

COMPACTCLEAN is a small gas heated thermal cleaning system, which removes organic contamination via thermal oxidation. It can be integrated easily into a workshop.

ADVANTAGES:

Low investment

Suitable for most polymers

Small footprint

Especially recommended for:

Non-return valves

Breaker plates

Hot runners

Needle valves, nozzles

ACCESSORIES

In addition to ist Thermal Cleaning Systems, SCHWING offers optionally a variety of accessories and post treatment systems.

For more information do not hesitate to contact us.

GMA sales representation

GMA MACHINERY ENTERPRISE CO. LTD. was founded in 1989 in Taiwan. At the beginning the company specialized in polymer injection molds design and manufacturing. In 1990, the design and manufacturing of extrusion dies for sheet and film was added to its portfolio. During the years the company has gained a great deal of experience in design as well as in T-dies research. Thanks to quality production and customer-oriented attitude GMA company has become the market leader in the area of T-dies. What is more, the company’s portfolio was diversified by adding coating machines. Most importantly, the advantage of GMA is the fact that the whole production process from design to manufacturing takes place in-house.

GMA products can be divided into following categories:

Extrusion sheet and film dies:

Simulation of polymer flow through the die with VEL® software - COMPUPLAST International

Die width from 10 mm up to 8000 mm

Die thickness from 0,08 mm up to 100 mm

Suitable for various material physical properties

Cooperation with German company for automatic adjustable extrusion dies production

Extrusion hollow sheet dies:

Different types

Suitable for various material physical properties

Long time experience

Screen changers:

Manually operated screen changers

Hydraulic operated non-stop screen changers

Dual piston continual screen changers

Feed blocks:

Different types - up to 9 materials

Fast adjusting of materials combination

Air knives:

Modular construction of air knives

Vacuum boxes, soft air boxes:

For high speed film processing lines (soft air boxes)

Suitable for PET films which requires temperature control (soft air boxes)

A necessity for those who require smooth film surface

Gear pumps

Static mixers

Coating products:

Laboratory coating lines

Slot/Slit coating dies

Multi-functional R&R coating pilot machines

The company was founded in 1991. As a result, our designers have many years of experience in designing dies and lines for plastic extrusion. In the course of the years, a great number of extrusion dies has been manufactured, both for common applications and for very special purposes. We have been using the 3D Solid Edge software for our design work since 2002. The software offers several tools including modules for stress and thermal computations and analysis. These supporting tools help us to solve even considerably challenging problems extremely quickly and efficiently.

The company was founded in 1991. As a result, our designers have many years of experience in designing dies and lines for plastic extrusion. In the course of the years, a great number of extrusion dies has been manufactured, both for common applications and for very special purposes. We have been using the 3D Solid Edge software for our design work since 2002. The software offers several tools including modules for stress and thermal computations and analysis. These supporting tools help us to solve even considerably challenging problems extremely quickly and efficiently.